Are you ready to take your metalworking skills to the next level? Imagine having the power to create precise holes in metal with ease and accuracy.

Whether you’re a seasoned DIY enthusiast or a curious beginner, mastering the use of a drill press can revolutionize your projects. This guide is designed specifically for you, aiming to demystify the process and unlock the full potential of this indispensable tool.

By the end of this article, you’ll not only understand how to use a drill press for metal but also gain the confidence to tackle any project with precision and skill. Keep reading, and discover how this knowledge can transform your workbench into a hub of creativity and efficiency.

Choosing The Right Drill Press

Using a drill press for metal needs the right machine. Picking the right drill press helps you work safely and accurately.

There are many types of drill presses and features to consider. Understanding these helps you choose the best one for metalwork.

Types Of Drill Presses

Drill presses come in different types. Each type suits different jobs and workshop sizes.

Here are common types used for metal:

- Bench Drill Press:Small and fits on a workbench. Good for light metal jobs.

- Floor Drill Press:Larger and stands on the floor. Used for bigger metal pieces.

- Radial Drill Press:Has an arm that moves. Ideal for drilling large metal parts.

- Magnetic Drill Press:Portable and sticks to metal surfaces. Great for on-site work.

Key Features For Metalworking

Metal drilling needs certain features for safety and precision. Look for these when choosing a drill press.

Important features include strong construction, adjustable tables, and good depth control.

- Solid Base and Frame:Keeps the drill steady during metal drilling.

- Adjustable Table:Moves up, down, and tilts for different angles.

- Depth Stop:Controls how deep the drill bit goes.

- Chuck Size:Holds larger drill bits for metal.

- Coolant System:Helps keep metal cool and extends tool life.

Power And Speed Considerations

Metal drilling needs enough power and the right speed. This avoids damage to the metal and drill bit.

Check motor power and speed range before buying.

- Motor Power:Higher power (around 3/4 HP or more) works better on tough metals.

- Variable Speed:Allows you to change speed for different metals and bit sizes.

- Speed Range:Lower speeds suit hard metals; higher speeds work for soft metals.

Essential Safety Precautions

Using a drill press for metal work can be safe if you follow basic rules. Safety helps prevent injuries and keeps your project on track.

Always focus on safety before you start drilling metal. This guide covers key steps to protect yourself.

Proper Protective Gear

Wear the right gear to protect your eyes, hands, and ears. Metal drilling can create sharp chips and loud noise.

- Safety goggles to protect your eyes from flying metal bits

- Gloves to keep your hands safe from sharp edges

- Ear protection to reduce noise from the drill press

- Wear close-fitting clothes to avoid getting caught

- Use a dust mask if metal dust is present

Securing The Workpiece

Keep your metal piece steady before drilling. Loose material can cause accidents and poor results.

Use clamps or a vise to hold the metal firmly. Never hold metal with your hands near the drill bit.

- Position the workpiece flat and stable

- Use clamps rated for metal work

- Check that the piece does not move before drilling

- Adjust the drill press table to the right height

Avoiding Common Hazards

Be aware of risks like sharp chips, spinning parts, and electrical hazards. Stay focused to avoid mistakes.

- Keep hands clear of the drill bit and moving parts

- Remove jewelry and loose items before drilling

- Turn off the machine before adjusting the workpiece

- Do not force the drill; let it cut gently

- Keep the area clean from metal shavings

- Check the drill press for damage before use

Preparing The Drill Press For Metal

Using a drill press for metal work needs careful preparation. Proper setup helps drill accurately and safely. This guide covers key steps to get ready for metal drilling.

Focus on choosing the right drill bits, setting the correct speed, and using lubrication. These steps protect your tools and improve your results.

Selecting The Correct Drill Bits

Not all drill bits work well on metal. Choose bits made of high-speed steel or cobalt. These bits last longer and cut through metal better.

- High-speed steel (HSS) bits for general metal drilling

- Cobalt bits for hard metals like stainless steel

- Carbide bits for very tough or abrasive materials

- Use the right size bit for your hole diameter

- Check bits for sharpness before use

Adjusting Speed Settings

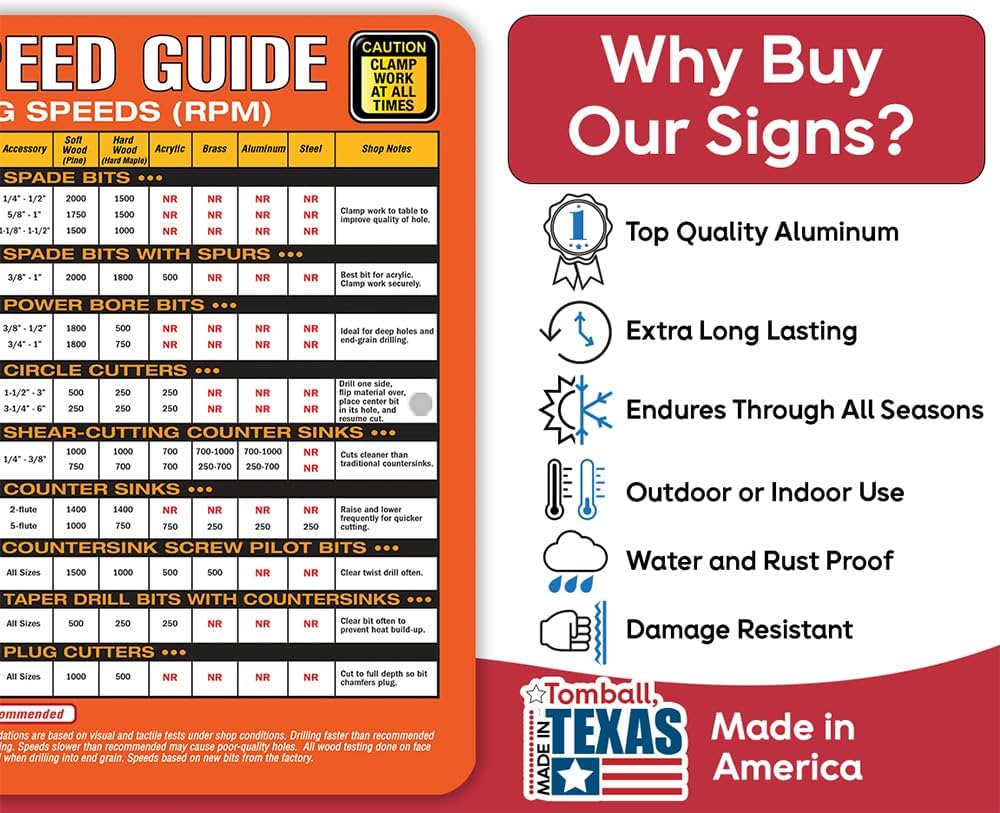

Metal drilling needs slower speeds than wood. Use the drill press speed chart below to pick the right speed for your bit size and metal type.

| Drill Bit Size (inches) | Speed (RPM) for Steel | Speed (RPM) for Aluminum |

| 1/16 – 1/8 | 3000 – 2500 | 4000 – 3500 |

| 3/16 – 1/4 | 1500 – 1200 | 2500 – 2000 |

| 5/16 – 3/8 | 1000 – 800 | 1500 – 1200 |

| 7/16 – 1/2 | 700 – 600 | 1000 – 900 |

Lubrication And Cooling Tips

Drilling metal creates heat. Use lubrication to cool the bit and metal. This prevents damage and extends bit life.

Follow these lubrication tips:

- Use cutting oil or a light machine oil

- Apply oil at the drill point before and during drilling

- Stop often to let the metal cool if drilling deep holes

- Clean metal shavings away to keep the area clear

Credit: www.amazon.com

Step-by-step Drilling Techniques

Using a drill press for metal requires careful steps to get clean holes. Following the right techniques helps prevent mistakes and ensures safety.

These steps cover marking, clamping, and drilling. Each part is important for a good result.

Marking And Center Punching

Start by marking the exact spot to drill. Use a sharp marker or scribe for a clear mark on the metal.

Next, use a center punch and hammer to make a small dent on the mark. This dent guides the drill bit and keeps it from slipping.

- Clean the metal surface before marking

- Use a ruler or measuring tool for accuracy

- Place the center punch firmly on the mark

- Tap the punch lightly to create a visible dent

Clamping And Aligning

Secure the metal piece firmly to the drill press table using clamps. This stops movement and improves safety.

Align the center punch mark with the drill bit before turning on the machine. Double-check the position to avoid mistakes.

- Use strong clamps suitable for metal

- Make sure the metal is flat and stable

- Adjust the drill press table height for comfort

- Lower the drill bit to check alignment before drilling

Drilling And Feed Rates

Start drilling at a slow speed. Use cutting oil on the bit to reduce heat and wear.

Apply steady, even pressure. Do not force the drill bit. Let the tool do the work to avoid breaking the bit.

- Choose the correct drill bit for metal

- Use slow to medium drill speed

- Add cutting fluid regularly

- Feed the bit gently into the metal

- Withdraw the bit occasionally to clear chips

Troubleshooting Drilling Issues

Using a drill press for metal can sometimes lead to problems. These issues affect your work quality and tool life.

Below are common drilling problems and how to fix them. Follow these tips to improve your drilling results.

Dealing With Bit Slippage

Bit slippage happens when the drill bit slips inside the chuck. This causes uneven holes and damages the bit and metal.

- Make sure the chuck is tight before starting.

- Use a key to fully tighten the chuck.

- Check the bit for wear and replace if dull.

- Use a bit with the right size for your chuck.

- Apply steady pressure during drilling, not too hard.

Preventing Overheating

Overheating can ruin your drill bit and metal. It makes drilling harder and causes rough holes.

| Cause | Solution |

|---|---|

| High speed | Reduce drill press speed for metal drilling |

| Too much pressure | Use gentle, steady pressure |

| No lubrication | Apply cutting oil or coolant regularly |

| Dull drill bit | Sharpen or replace the bit |

Fixing Misaligned Holes

Misaligned holes occur when the metal or drill bit moves during drilling. This leads to inaccurate results.

- Secure the metal firmly with clamps or a vise.

- Mark the drilling spot clearly with a center punch.

- Check drill bit alignment before turning on the press.

- Slow down drilling speed for better control.

- Use a pilot hole to guide the main drill bit.

Credit: www.amazon.com

Maintenance For Long-lasting Performance

Keeping your drill press in good shape helps it work well for years. Regular maintenance stops problems before they start.

Follow simple steps to clean, check, and fix parts. This guide shows how to care for your drill press.

Cleaning And Lubricating

Clean your drill press after each use. Remove dust, metal shavings, and oil build-up to keep parts moving smoothly.

- Wipe down the table and base with a soft cloth.

- Use a brush to clear dust from gears and motor vents.

- Apply machine oil to moving parts like the spindle and quill.

- Avoid over-lubricating to prevent dirt from sticking.

- Check the manufacturer’s guide for specific lubricant types.

Checking Belt Tension

The belt drives the drill press motor. Proper tension keeps it running well and avoids slipping or damage.

| Check | What to Look For | Action |

|---|---|---|

| Belt Tightness | Press the belt halfway between pulleys. It should move about half an inch. | Tighten if too loose; loosen if too tight. |

| Belt Condition | Look for cracks, frays, or worn spots. | Replace if damaged to avoid breakage. |

| Pulleys | Ensure pulleys are clean and aligned. | Adjust alignment if needed to prevent belt wear. |

Inspecting And Replacing Parts

Check parts regularly to find wear or damage. Replace parts to keep the drill press safe and precise.

- Look at the chuck for cracks or looseness.

- Check the spindle for smooth rotation and no wobble.

- Examine the motor brushes for wear and replace if thin.

- Inspect the power cord for cuts or frays.

- Replace any damaged parts with ones from the drill press brand.

:max_bytes(150000):strip_icc()/JS_1864-2008bd548fb548db8f5729d54b71976b.jpg)

Credit: www.woodmagazine.com

Frequently Asked Questions

How Do I Choose The Right Drill Bit For Metal?

Select drill bits made of high-speed steel or cobalt for metal. Match the bit size to your hole diameter. Use sharp, clean bits to ensure precision and avoid metal damage.

What Safety Precautions Are Essential When Using A Drill Press?

Always wear safety goggles and gloves. Secure the metal firmly with clamps. Keep loose clothing away and maintain a clean workspace to prevent accidents.

How Do I Prevent Metal From Overheating While Drilling?

Use cutting oil or lubricant to reduce friction. Drill at a slow speed and apply steady pressure. Pause frequently to allow the metal to cool down.

Can I Drill Through Thick Metal With A Drill Press?

Yes, but use a powerful drill press and a cobalt bit. Drill slowly with steady pressure. For very thick metal, consider drilling pilot holes first.

Conclusion

Using a drill press for metal makes drilling easier and more accurate. Always keep safety in mind and wear proper gear. Choose the right drill bit for the metal type you work with. Take your time and measure carefully before drilling.

Practice helps improve your skill and confidence. With patience and care, your metal projects will turn out well. Remember, steady hands and the right tools bring the best results. Keep learning and enjoy working with your drill press.